Learning how to make beeswax candles opens the door to creating natural, eco-friendly candles that enhance the ambiance of any space. This craft combines artistry with sustainability, offering a rewarding experience for beginners and seasoned crafters alike.

By understanding the essential materials, preparation techniques, and artistic methods involved, you can craft stunning candles that not only serve as functional items but also as beautiful decorative pieces. From sourcing quality beeswax to finishing your candles with personal touches, the process is both enjoyable and fulfilling.

Materials Needed for Making Beeswax Candles

Creating high-quality beeswax candles requires selecting the right materials to ensure a clean, sustainable, and aesthetically pleasing product. Understanding the materials involved, including the types of beeswax, wicks, containers, and potential additives, is essential for achieving optimal results. This section provides a comprehensive overview of these materials, highlighting options suitable for both beginners and experienced candlemakers.

The choice of materials not only influences the appearance and burning characteristics of the candles but also impacts environmental sustainability and safety. Proper sourcing and selection of eco-friendly options contribute to creating candles that are both beautiful and responsible. Below, a detailed comparison of common materials used in beeswax candle making is presented in a structured table for clarity.

Materials Comparison Table

| Material | Description | Quantity |

|---|---|---|

| Beeswax | Natural wax produced by honeybees; can be in block, pellet, or sheet form. Types include yellow, white, or filtered beeswax. Known for its clean burn and subtle honey scent. | 1-5 pounds for a small batch; adjust based on candle size and quantity |

| Wicks | Material varies from cotton, hemp, or wood. Cotton wicks are common, often with metal or paper cores. Eco-friendly options include unbleached cotton or hemp. Wicks should be appropriately sized for candle diameter to ensure proper burning. | Multiple wicks, depending on candle size; typically 1-3 wicks per candle |

| Containers | Receptacles such as glass jars, metal tins, or ceramic holders. Should be heat-resistant, non-toxic, and visually appealing. Clear glass jars showcase the wax, while tins provide portability and minimalistic aesthetics. | One per candle; size varies from small tealights to large pillar holders |

| Additives | Description | Quantity |

| Essential oils | Natural scents used to fragrance the candles, such as lavender, eucalyptus, or peppermint. Should be added in small amounts to avoid affecting burn quality. | 1-10% of total wax weight |

| Colorants | Natural or synthetic dyes used to tint the beeswax or the candle surface. Beeswax naturally has a warm hue, but colorants can enhance or alter its appearance. | Used sparingly; typically a few drops or small amounts of pigment |

Sourcing Quality Beeswax and Eco-Friendly Wicks

Ensuring the purity and sustainability of beeswax and wicks is crucial for producing high-quality candles that are environmentally responsible. When sourcing beeswax, consider the following:

- Local Beekeepers: Purchasing directly from local apiaries supports sustainable practices and guarantees freshness and purity. Look for raw or minimally processed beeswax that is free from chemical additives.

- Certified Organic Suppliers: Opt for suppliers that provide organic certification, ensuring the beeswax is produced without pesticides or synthetic chemicals.

- Reputation and Reviews: Choose reputable brands with positive reviews regarding quality and ethical sourcing.

Eco-friendly wicks should be selected based on their materials and production methods:

- Unbleached Cotton Wicks: Naturally dyed and processed without chemicals, these wicks burn cleanly and safely.

- Hemp Wicks: Made from natural hemp fibers, offering a biodegradable and sustainable alternative to synthetic wicks.

- Wooden Wicks: Crafted from sustainably sourced wood, providing a unique aesthetic and steady burn, often with a crackling sound reminiscent of a fireplace.

“Choosing ethically sourced beeswax and eco-friendly wicks ensures that your candles are not only beautiful but also environmentally responsible and safe for users.”

Preparing Beeswax for Candle Making

Proper preparation of beeswax is a crucial step in ensuring quality and safety in candle making. This process involves cleaning, melting, and filtering the beeswax to remove impurities, debris, and contaminants that can affect the final product. By adhering to meticulous preparation methods, candle makers can achieve cleaner, more consistent candles with better burn qualities and an appealing appearance.

Effective preparation of beeswax not only enhances the aesthetic and functional qualities of the candles but also extends their lifespan and performance. The subsequent procedures focus on safe and efficient techniques to melt and filter beeswax, maintaining its natural properties while eliminating undesirable impurities that may have accumulated during harvesting or storage.

Cleaning and Melting Beeswax

Cleaning beeswax involves removing any residual debris, pollen, or hive wax remnants that may compromise the purity of the final product. The melting process requires careful temperature control to preserve the beeswax’s natural qualities and prevent degradation. Ensuring safety and preventing contamination are essential factors during this stage.

Below are detailed steps for safely melting beeswax using appropriate equipment and maintaining optimal temperature conditions:

- Preparation of Equipment: Gather a double boiler or melting pot, a thermometer, and a heat-resistant stirring utensil. Ensure all tools are clean to prevent introducing foreign particles or contaminants into the beeswax.

- Setting Up the Double Boiler: Fill the lower compartment of the double boiler with water and place it on a stove or heat source. Position the beeswax in the upper compartment or a heat-proof container within the double boiler. This method provides gentle, even heat, reducing the risk of overheating.

- Melting the Beeswax: Turn on the heat, gradually bringing the water to a simmer. Place the beeswax in the upper compartment, allowing it to melt slowly. Stir gently and consistently to promote even melting.

- Maintaining Correct Temperature: Keep the temperature of the beeswax between 140°F to 160°F (60°C to 70°C). Use a thermometer to monitor the temperature closely. Avoid exceeding 170°F (77°C) to prevent decomposition or change in scent and color.

- Filtering the Beeswax: Once fully melted, pour the beeswax through a fine mesh strainer or cheesecloth into a clean container to remove residual debris and impurities. This step ensures a pure, smooth wax ready for pouring.

Tips for Safe Melting:

- Always keep a close watch on the melting process to prevent overheating, which can produce fumes or degrade the wax quality.

- Use heat-resistant gloves when handling hot containers and wax to prevent burns.

- Work in a well-ventilated area to avoid inhaling any fumes released during melting.

- Never leave melting beeswax unattended to reduce fire risk and ensure safety.

Maintaining the correct temperature during melting preserves the beeswax’s natural aroma, color, and scent while preventing undesirable changes or contamination.

Selecting and Preparing Candle Wicks

Making beeswax candles involves several important steps to ensure a clean burn, vibrant appearance, and overall safety. Among these, choosing the right wick type and preparing it correctly are crucial to achieving consistent and beautiful candles. Properly prepared wicks contribute to an even melt pool, minimal smoke, and optimal scent release, making your candle-making process both enjoyable and successful.A selection of appropriate wicks depends on the size of the candle and the characteristics of beeswax, which is naturally harder and burns at a different rate compared to other waxes.

The right wick not only ignites easily but also maintains a steady flame throughout the burn time, preventing tunneling or incomplete melting of the wax. Proper preparation, including measuring, cutting, and securing the wick, ensures that your candles are both functional and visually appealing.

Types of Candle Wicks Suitable for Beeswax Candles

To optimize the burning process, it is essential to choose the correct wick type for beeswax candles. Different wick materials and constructions offer various advantages in terms of burn quality, safety, and aesthetic appeal.

- Cotton Wicks: The most common choice, available in various thicknesses and braided for strength. They provide a clean, steady burn and are compatible with beeswax’s natural properties.

- Wooden Wicks: Made from thin slices of sustainable wood, these wicks create a unique crackling sound and a cozy ambiance. They are highly suitable for beeswax candles due to their robust burning characteristics.

- Paper-Core Wicks: These wicks feature a paper core wrapped in cotton or other fibers, offering increased rigidity and stability, especially for larger or thicker candles.

Choosing the appropriate wick involves considering the candle’s diameter, the wax’s density, and the desired burn characteristics. For beeswax candles, cotton and wooden wicks are often preferred because they enhance the natural burning qualities of beeswax, provide a cleaner burn, and prevent excessive soot formation.

Measuring and Cutting Wicks for Different Container Sizes

Accurate measurement and cutting of wicks are fundamental to ensuring the candle burns evenly and safely. Wicks that are too short can cause the flame to drown in wax, while excessively long wicks may produce a high, flickering flame or soot.

The general guideline for wick length involves adding approximately 1 inch (2.5 cm) to the height of the container. This excess allows the wick to extend above the wax surface, facilitating ignition and maintaining flame stability.

Example: For a 3-inch (7.5 cm) tall container, cut the wick to around 4 inches (10 cm) in length.

- Use sharp scissors or wick cutters to achieve a clean, straight cut, which helps prevent fraying and ensures the wick’s integrity during burning.

- If making multiple candles, prepare all wicks uniformly to maintain consistency in burn behavior and aesthetic appearance.

Securing Wicks in Containers Using Labels or Adhesives

Properly anchoring the wick at the center of the container is vital to maintain a straight burn path and prevent the wick from shifting during the pouring process or while curing.

Several methods exist to secure the wick in place, with the choice depending on the container type and personal preference:

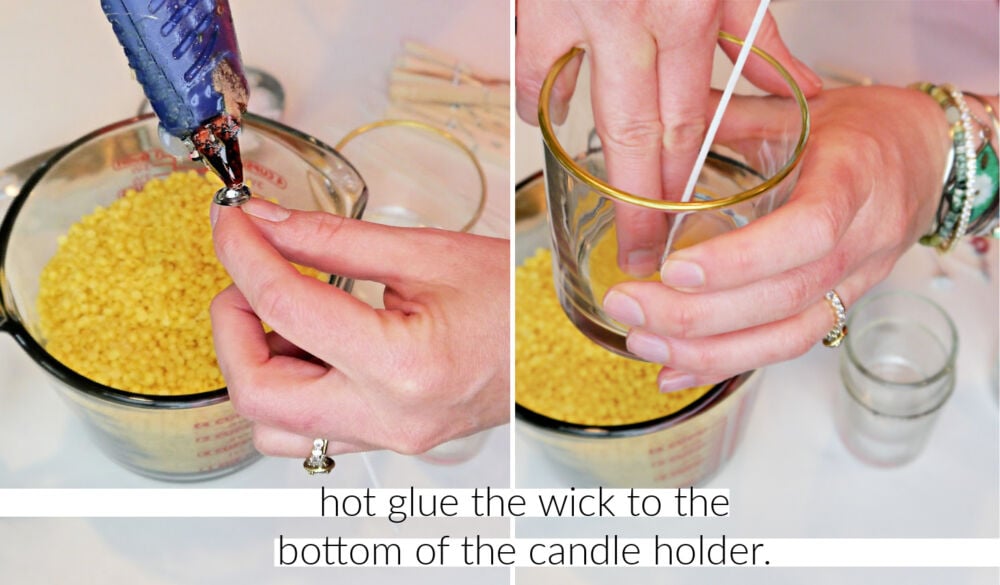

- Using Labels or Wick Stickers: Small adhesive labels or specially designed wick stickers can be placed at the bottom center of the container before pouring the wax. The wick is then pressed into the adhesive, holding it securely in position.

- Applying Hot Glue or Wax: A small dab of hot glue or melted beeswax on the bottom of the wick base can anchor it firmly. This method is especially effective for thicker or heavier wicks.

- Centering with Wick Holders or Clips: Metal or silicone wick centering devices can be placed atop the container, with the wick secured through a hole or slit, ensuring perfect centering during pouring and cooling.

Ensuring the wick remains centrally aligned and upright during the wax setting process promotes an even burn and enhances the aesthetic appeal of your finished candles. It is beneficial to double-check the wick’s position before the wax solidifies completely, adjusting if necessary to maintain the desired alignment.

Pouring and Shaping Beeswax Candles

Making beeswax candles involves precise pouring and shaping techniques to achieve a beautiful, smooth finish and desired design. Proper handling during this stage ensures that the candles are both aesthetically pleasing and functional, with no unwanted air pockets or surface imperfections. Whether you are pouring into molds, containers, or shaping by hand, attention to detail during this phase is crucial for professional-looking results.During the pouring process, the goal is to distribute the melted beeswax evenly into your chosen molds or containers while minimizing the formation of air bubbles and surface imperfections.

Achieving a smooth surface requires careful control of temperature and pouring speed, along with techniques to release trapped air. Shaping options vary from pouring into pre-made molds to layering beeswax or embedding decorative elements, allowing for creative and unique designs.

Pouring Melted Beeswax into Molds or Containers

To ensure a successful pour, it is essential to follow a systematic procedure that promotes even filling and prevents defects:

- Allow the melted beeswax to cool slightly to about 65-70°C (149-158°F). This temperature is ideal for pouring, reducing the likelihood of cracks or surface imperfections.

- Position your molds or containers on a stable, level surface in a well-ventilated area.

- Use a pouring jug or spouted container to control the flow of beeswax, minimizing spills and drips.

- Pour slowly and steadily, starting at the center of the mold or container to promote even distribution.

- Fill each mold or container to the desired level, leaving a small margin at the top to allow for expansion and surface smoothing.

During pouring, it is common for air bubbles to form. To minimize this, you can tap the mold gently or use a toothpick or needle to release trapped bubbles before the wax solidifies. Ensuring a slow, steady pour and maintaining a consistent temperature are key practices for achieving a smooth, bubble-free surface.

Techniques for Achieving Smooth Surfaces and Avoiding Air Bubbles

Smooth surfaces and bubble-free candles reflect craftsmanship and enhance visual appeal. Here are some effective techniques:

- Pour the beeswax at a consistent temperature, avoiding sudden temperature changes that can cause surface imperfections.

- Pour slowly to reduce turbulence, which often traps air bubbles within the wax.

- Gently tap or vibrate the mold after pouring to encourage air bubbles to rise to the surface and escape.

- Use a heat gun or a small torch briefly over the surface to melt any surface bubbles or imperfections, smoothing the finish.

- Allow the wax to cool undisturbed, preventing surface disturbances caused by movements or drafts.

Maintaining a clean workspace free of drafts and using proper pouring techniques are essential for achieving professional-quality candles with smooth surfaces.

Shaping Candles with Molds, Layering, and Decorative Embellishments

Shaping options offer a wide range of creative possibilities, from traditional molds to intricate layered designs or embedding decorative elements within the wax:

- Molds: Silicone, metal, or plastic molds come in various shapes and sizes. Pour the melted beeswax into the mold, ensuring it is clean and dry. For detailed shapes, consider using a mold release agent to facilitate easy removal.

- Layering: Pour beeswax in thin layers, allowing each to cool slightly before adding the next. This technique creates layered effects and allows for color variation or textured finishes.

- Embedding Decorative Elements: Small objects such as dried flowers, herbs, or essential oil-infused elements can be embedded during the initial pour or between layers. Position these decorations carefully to prevent shifting or damage during the setting process.

For more complex designs, you can combine these techniques—pouring into molds while embedding decorative elements or layering different colored beeswax for a multicolored finish. Patience during each step ensures a clean, professional look, and experimentation with different shapes and decorations can lead to unique and personalized creations.

Cooling and Finishing Candles

Creating beautifully finished beeswax candles requires careful attention during the cooling and final touches stages. Proper handling at this point ensures the candles not only look their best but also maintain structural integrity, preventing common issues such as cracking or sinkholes. Achieving a polished, professional appearance involves a combination of appropriate cooling techniques, precise wick management, decorative enhancements, and surface cleaning methods.

By following these best practices, candle makers can ensure their creations are both aesthetically pleasing and durable.Cooling is a critical step that influences the final appearance and quality of beeswax candles. Rapid cooling can lead to surface cracks or uneven textures, while slow, controlled cooling promotes a smooth, uniform finish. It is advisable to allow the candles to cool gradually at room temperature, away from drafts or temperature fluctuations.

For larger candles, placing them on a level, insulated surface can help prevent warping or sinkholes caused by uneven cooling. Using a cooling rack or placing the candles on a soft, insulating material ensures even heat dissipation, thereby minimizing the risk of cracks and surface imperfections.Trimming wicks and adding decorative touches lend a professional and personalized finish to the candles.

Once the candle has cooled sufficiently but is still warm enough to trim without cracking, cut the wick to about ¼ inch to prevent excessive smoke and soot during burning. For aesthetic enhancements, consider adding decorative tops such as carved wax accents, embedded botanicals, or metallic embellishments that complement the candle’s style. Fragrant oils or essential oils can also be applied at this stage to introduce subtle scents, but ensure they are compatible with beeswax to avoid melting or discoloration.Surface polishing and cleaning are essential for presenting a clean, attractive candle.

After cooling, gently dust off any residual debris or fingerprints with a soft, lint-free cloth. For a glossy finish, lightly buff the surface using a clean cotton or microfiber cloth, being careful not to scratch or damage the wax. If the surface appears dull or has minor imperfections, a small amount of warm, natural beeswax rubbed onto the surface can restore luster and provide an extra layer of protection.

For a more refined appearance, some artisans use a soft brush to remove dust from intricate details, ensuring every part of the candle looks pristine and ready for display or gifting.

Adding Fragrances and Decorations

Creating beeswax candles that are both fragrant and visually appealing enhances their aesthetic and sensory appeal. Incorporating natural scents and decorative elements must be done carefully to preserve the quality and safety of the final product. Proper techniques ensure that fragrances are well-distributed without affecting the candle’s burn quality, while decorations add unique touches without compromising the candle’s integrity or safety during burning.Integrating fragrances and decorative embellishments requires attention to detail and an understanding of the materials used.

When adding scents, it is important to select appropriate essential oils or natural fragrances that complement beeswax’s inherent aroma. Decorations, such as embeds, colorants, or embellishments, should be chosen for their safety and compatibility with candle wax. Employing the correct procedures ensures that these elements enhance the candle’s visual and aromatic qualities while maintaining safety and functionality.

Infusing Beeswax with Fragrances

Incorporating essential oils into beeswax candles should be approached with care to ensure the scents are evenly dispersed and do not negatively impact the candle burn. The most effective method involves adding fragrances at specific stages during the candle-making process:

- Use high-quality essential oils or natural fragrances, ideally pure and 100% natural, to avoid impurities that could cause uneven burning or soot.

- Choose oils with a low flash point (generally below 150°F or 65°C) to prevent ignition during the melting process.

- When the beeswax has reached a temperature of approximately 160°F (71°C), add the essential oils in small quantities—generally 1-3% of the total wax weight—stirring thoroughly to ensure even distribution.

- Mix gently but thoroughly to prevent introducing air bubbles or disturbing the wax’s structure. This can be achieved with a clean, heat-resistant stirrer or spatula.

- Allow the wax to cool slightly before pouring, as high temperatures can cause the scent to volatilize and diminish.

Adding fragrances at the right temperature and in appropriate proportions ensures a subtle, long-lasting scent without compromising the candle’s safety or burn quality.

Decorative Embeds, Colorants, and Embellishments

Decorating beeswax candles offers a personalized touch and enhances their visual appeal. When selecting and preparing decorative elements, it is essential to prioritize safety and compatibility with candle wax.

- Embeds such as dried flowers, herbs, or small decorative objects should be non-flammable and specifically designed for candle use to prevent fire hazards.

- Natural colorants like beeswax dyes, mica powders, or plant-based pigments can be added to the wax before pouring to achieve vibrant or subtle hues. These should be heat-safe and compatible with beeswax without affecting burn quality.

- For embellishments such as metallic or glitter accents, select non-toxic, cosmetic-grade products formulated for use with candles. Avoid plastic or synthetic materials that could melt or produce harmful fumes.

- When embedding objects, position them carefully within the mold or on the surface after pouring, ensuring they are securely fixed and evenly distributed.

- To add decorative layers or textures, pour a small amount of wax in the mold, place the embellishments, then pour the remaining wax to encapsulate them fully.

Proper preparation and selection of decorations not only enhance the aesthetic appeal but also ensure the safety and quality of the finished candle, making it suitable for both gifting and personal enjoyment.

Troubleshooting Common Issues in Beeswax Candle Making

Making beeswax candles can be a rewarding craft, but occasionally, challenges may arise that affect the final product’s appearance and performance. Understanding how to identify and resolve these common issues is essential for producing beautiful, functional candles consistently. Addressing problems early can save time, materials, and frustration, ensuring your candle-making experience remains enjoyable and successful.In this section, we will explore the typical problems encountered during beeswax candle making, such as uneven burning, cracking, or poor adhesion.

We will provide detailed solutions and preventive measures for each issue, equipping you with practical tips to troubleshoot effectively and improve your craft.

Uneven Burning or Tunneling

Uneven burning, often characterized by a candle burning down the center while leaving wax on the sides, can occur due to improper wick size or inadequate initial burn. This issue diminishes the aesthetic and reduces candle longevity.

- Ensure you select the correct wick size for the candle diameter. A wick that is too small will cause insufficient heat to melt the wax evenly, leading to tunneling.

- Perform an initial burn for 2-3 hours until the wax melts across the entire surface. This creates a memory burn, helping the candle burn evenly in subsequent uses.

- Trim the wick to approximately ¼ inch before each use to prevent excessive flame height, which can cause uneven burning and soot.

- Use a wick with a proper core, such as cotton or hemp, to promote steady, even flames.

- Place candles on a stable, draft-free surface to avoid uneven airflow affecting the flame.

Cracking or Surface Cracks in the Wax

Cracks can develop on the surface of beeswax candles, affecting their appearance and structural integrity. Cracks often form due to temperature fluctuations or improper pouring techniques.

Cracking typically results from cooling the wax too quickly or uneven heating during pouring. To prevent this:

- Pour beeswax at a controlled, moderate temperature—generally around 160-180°F (71-82°C)—to promote smooth solidification.

- Avoid pouring when the wax is too hot, as rapid cooling can cause stress and surface cracks.

- Allow candles to cool gradually in a stable environment, avoiding drafts or sudden temperature changes.

- Use a double boiler method to ensure even heating and consistent temperature control during melting and pouring.

Poor Adhesion of Wax to Container

When beeswax does not adhere properly to the container, it can cause issues with stability and safety, especially with decorative or container candles.

To improve wax adhesion:

- Ensure the container is clean and dry before pouring wax to eliminate any dust or moisture that could hinder adhesion.

- Pre-warm the container slightly to reduce temperature differences between the wax and the container surface.

- Pour beeswax at the recommended temperature to allow proper bonding—typically around 160°F (71°C).

- If adhesion remains an issue, consider treating the container with a thin layer of a suitable primer or a mixture of beeswax and a small amount of resin to enhance sticking.

Surface Bubbles or Air Pockets

Bubbles or air pockets can mar the surface of your candles, giving an uneven appearance and potential structural weaknesses.

To minimize bubbles:

- Pour the wax slowly and steadily to avoid trapping air.

- Pre-warm the mold or container to prevent rapid cooling that causes bubbles.

- Tap or gently vibrate the mold after pouring to encourage air bubbles to rise and escape.

- Use a toothpick or small tool to pop visible bubbles on the surface immediately after pouring.

Excess Soot or Smoke During Burning

Excessive soot and smoke indicate issues with wick size, wax quality, or airflow.

Solutions include:

- Choose a wick appropriately sized for your candle’s diameter and wax type.

- Trim the wick regularly to maintain a flame height of about ¼ inch.

- Ensure the wax is clean and free of impurities, as contaminants can cause soot.

- Burn candles in draft-free areas to prevent uneven airflow that can cause flickering and soot.

- Consider adding a small amount of natural resin or other additives to the beeswax to improve combustion efficiency.

Proper troubleshooting and preventive measures are essential components of successful beeswax candle making. By carefully selecting materials, controlling temperature, and paying attention to the burning environment, you can significantly reduce common issues and produce high-quality, beautiful candles.

Final Wrap-Up

Mastering how to make beeswax candles allows you to create unique, eco-conscious candles tailored to your taste. With the right materials, techniques, and a touch of creativity, you can produce stunning candles that brighten your home and make thoughtful gifts. Embrace this craft to enjoy the satisfaction of handmade excellence and the natural beauty of beeswax candles.