Learning how to extract honey with an extractor is essential for beekeepers seeking to maximize yield and preserve honey quality. This process not only streamlines honey harvesting but also ensures the health and safety of the hive are maintained throughout. Understanding the components and proper procedures involved can significantly enhance the efficiency and success of your honey extraction efforts.

An effective honey extraction process involves carefully preparing the hive, selecting the appropriate extractor type, and following precise steps from loading the honeycombs to storing the honey. By mastering these techniques, beekeepers can achieve cleaner, higher-quality honey while minimizing waste and damage to the combs.

Introduction to Honey Extraction with an Extractor

Honey extraction using an extractor is a pivotal step in harvesting honey efficiently and maintaining its quality. This process harnesses specialized equipment designed to simplify the extraction, reduce honey wastage, and ensure that the honey is collected in a clean and organized manner. Employing an extractor not only streamlines the workflow for beekeepers but also promotes the preservation of hive health and honey purity.

An extractor typically consists of several key components that work together to spin honey from the honeycombs without damaging the delicate structure of the wax frames. This method offers a significant advantage over traditional manual scraping or crushing techniques, as it minimizes honey contamination and reduces the effort required for harvesting. From hive to jar, the process flow involves careful handling, extraction, filtration, and finally, packaging, ensuring that the honey maintains its natural flavor, aroma, and nutritional values.

Components of a Honey Extractor and Their Functions

Understanding the basic components of a honey extractor is essential for efficient operation and maintenance. Each part plays a crucial role in the extraction process, contributing to a smooth workflow and high-quality honey output.

| Component | Description | Function |

|---|---|---|

| Drum or Barrel | A cylindrical container that holds the honeycombs during spinning. | Supports the frames and contains the centrifugal force needed to extract honey. |

| Inner Frame or Basket | Holds the honeycomb frames securely inside the drum. | Ensures the frames are evenly spaced and stabilized during spinning, preventing damage. |

| Hand Crank or Motor | Operates the spinning mechanism manually or electrically. | Creates centrifugal force to fling honey out of the combs and into the walls of the drum. |

| Spindle or Axle | The central axis around which the drum spins. | Facilitates smooth rotation and maintains balance during operation. |

| Drain or Spout | Outlet located at the bottom of the extractor. | Allows honey to flow out after extraction, directing it into collection containers. |

| Lid or Cover | Protects the honeycomb frames and prevents contamination. | Prevents debris, insects, and dust from entering during extraction. |

Overview of the Honey Extraction Process Flow

The pathway from hive to jar involves several carefully coordinated steps to ensure honey is harvested efficiently while maintaining its quality. Each stage plays a vital role in the overall process, from handling the frames to storing the finished product.

- Harvesting Frames: Carefully removing honey-filled frames from the hive with minimal disturbance to the bees. Proper handling prevents damage to the comb and preserves hive health.

- Uncapping the Cells: Using a hot knife or uncapping fork to remove the wax caps sealing the honey cells. This step is crucial to allow honey to flow freely during extraction.

- Loading Frames into the Extractor: Positioning the uncapped frames into the extractor’s basket or frame holders, ensuring they are secured and evenly spaced for balanced spinning.

- Spinning the Extractor: Operating the extractor—either manually or electrically—to generate centrifugal force. This causes honey to be flung outward from the combs and collect on the sides of the drum.

- Honey Collection: After spinning, honey flows down the walls of the extractor and is drained through the spout into containers. Multiple spins may be required to maximize yield.

- Filtering and Bottling: The honey is strained to remove residual wax or debris, then transferred into jars or containers for storage or sale.

By following this systematic process, beekeepers can ensure a high-quality honey harvest that preserves the natural characteristics of the honey while maximizing efficiency and minimizing waste.

Types of Honey Extractors and Their Suitability

Choosing the appropriate honey extractor is a crucial step in ensuring efficient honey harvesting while maintaining the quality and integrity of the honey and beeswax combs. Different types of extractors cater to various sizes of apiaries, levels of automation, and personal preferences. Understanding their features and suitability helps beekeepers make informed decisions tailored to their specific needs.

Honey extractors primarily fall into manual and electric categories, each offering distinct advantages depending on the scale of operation, budget, and ease of use. Additionally, the design configurations—namely tangential and radial extractors—play a significant role in the efficiency of honey extraction and the preservation of combs. The following sections provide detailed insights into these types, their features, and appropriate applications.

Manual versus Electric Honey Extractors

Manual and electric honey extractors differ mainly in their operation mode, efficiency, and user experience. The choice between the two depends on factors such as honey production volume, available manpower, and budget constraints. Both types serve the purpose of extracting honey but vary considerably in terms of ease and speed.

- Manual Honey Extractors: These extractors operate via hand-cranking, requiring physical effort from the user. They are typically more cost-effective, portable, and suitable for small-scale beekeepers with limited honey production. Manual extractors demand more time and labor, which may become a limiting factor during peak harvest periods. They are ideal for hobbyist beekeepers or those managing fewer colonies.

- Electric Honey Extractors: Equipped with a motor that automates the spinning process, electric extractors significantly reduce manual effort and increase efficiency. They can process larger quantities of honey in a shorter time, making them suitable for commercial or semi-commercial operations. Electric models often come with adjustable speed controls, safety features, and sometimes automated functions, enhancing ease of use and consistency.

Designs of Honey Extractors: Tangential vs. Radial

The internal design of a honey extractor influences how efficiently honey is extracted and how well the combs are preserved. Two primary configurations, tangential and radial, are widely used, each with specific advantages depending on the beekeeper’s operational scale and extraction preferences.

- Tangential Extractors: In tangential extractors, frames are inserted so that the beeswax side faces outward, allowing honey to be spun out from one side of the frame at a time. This design is often simpler and more affordable, making it suitable for small-scale beekeepers. However, it requires flipping the frames to extract honey from both sides, which increases handling time and potential disturbance to the bees.

- Radial Extractors: Radial extractors hold frames in a horizontal position with the honey side facing outward, enabling honey to be spun out from both sides simultaneously without flipping. This design enhances extraction efficiency, reduces handling time, and minimizes disturbance to the bees. Radial extractors are more advanced and typically favored by larger apiaries or commercial operations due to their higher throughput and ease of use.

Features and Specifications of Honey Extractor Models

Various honey extractor models are available on the market, each tailored to different operational capacities and preferences. Key features such as capacity, material, motor power, and design influence their suitability for specific beekeeping setups. The following table summarizes features across popular models:

| Model | Type | Capacity | Operation Mode | Material | Motor Power | Suitable For |

|---|---|---|---|---|---|---|

| Premium Manual Tangential | Manual | 2-4 frames | Hand-crank | Food-grade stainless steel | N/A | Small hobby apiaries |

| Standard Electric Radial | Electric | 4-8 frames | Electric motor | Stainless steel with plastic components | 150-300W | Medium-scale beekeepers |

| Commercial Heavy-duty Radial | Electric | 10+ frames | High-power motor with variable speed | Heavy-duty stainless steel | 500-1000W | Large apiaries and honey processing facilities |

Preparing for Honey Extraction

Efficient and safe honey extraction begins with thorough preparation. Properly harvesting honeycombs from the hive and ensuring all equipment is clean and ready for use are crucial steps that influence the quality and safety of the final product. Well-planned preparation not only streamlines the extraction process but also minimizes the risk of contamination and equipment failure, ensuring a successful honey harvest.A systematic approach to preparation involves careful removal of honeycombs, meticulous cleaning of extraction tools, and assembling the necessary supplies for an efficient workflow.

Attention to detail during these initial stages contributes significantly to preserving honey’s natural flavor, aroma, and purity, ultimately supporting the health of the hive and the beekeeper’s productivity.

Harvesting Honeycombs Safely from Hives

Harvesting honeycombs requires a gentle yet precise method to ensure the safety of both the beekeeper and the bees. Using appropriate protective gear such as hive suits, gloves, and veils protects against stings and allows for confident handling of the hive components. Before removal, it is essential to inspect the hive for optimal honey maturity, typically when the honey cells are capped, indicating readiness for extraction.Careful removal of honey frames involves loosening the frames from the hive without damaging the combs or disturbing the bees unnecessarily.

Using a hive tool helps pry frames loose, while a bee brush can gently displace any remaining bees from the combs. Once detached, the frames should be placed in a clean, secure container that prevents crushing or contamination during transport to the extraction area.

Cleaning and Sanitizing Extractor Components

Maintaining hygiene standards in honey extraction is vital for producing high-quality honey and preventing spoilage or bacterial contamination. Before use, all extractor components—including drums, baskets, and spigots—must be thoroughly cleaned with warm water and a mild, food-safe detergent. Rinsing thoroughly removes any residual soap, which can impart unwanted flavors or harm the honey.Sanitization involves disinfecting the equipment to eliminate bacteria, mold, or yeast that could compromise honey quality.

Using a food-grade sanitizing solution or a mixture of diluted vinegar and water is effective for this purpose. After sanitizing, all components should be rinsed with clean water and allowed to air dry completely. Ensuring the extractor parts are dry and free of residues reduces the risk of fermentation or spoilage in the harvested honey.

Tools and Supplies Checklist for Efficient Extraction

A comprehensive list of tools and supplies enables a smooth honey extraction process, reducing delays and equipment mishaps. The following items are essential:

- Protective gear (hive suit, gloves, veil) for safety and hygiene

- Hive tool for frame removal and hive manipulation

- Bee brush for clearing bees from honeycombs

- Sharp knife or hive cutter for cutting combs if necessary

- Food-safe containers or buckets for storing honeycombs

- Honey extractor (manual or motorized, depending on scale)

- Uncapping knife or fork for removing wax caps from honey cells

- Uncapping tank or tray to catch drippings during uncapping process

- Fine mesh strainer or cheesecloth for filtering honey

- Food-grade sanitizing solution for equipment cleaning

- Measuring cups and jars for portioning and storage

- Labels and markers for proper identification and tracking

Ensuring all these tools are prepared and in good working condition prior to harvest greatly enhances efficiency and safety during honey extraction. Proper organization, along with adherence to hygiene protocols, helps maintain the integrity and quality of the honey from hive to jar.

Post-extraction procedures

Following the honey extraction process, careful handling and processing are essential to ensure the honey maintains its quality, clarity, and freshness. Proper post-extraction procedures safeguard the product from contamination, preserve its natural flavor, and extend its shelf life, making it ready for packaging and eventual consumption.Effective post-extraction management begins immediately after honey is removed from the extractor. This stage involves filtering to remove impurities, clarifying to improve transparency, thorough cleaning of equipment, and appropriate storage solutions.

Each step plays a vital role in maintaining the integrity of the honey and ensuring it meets quality standards.

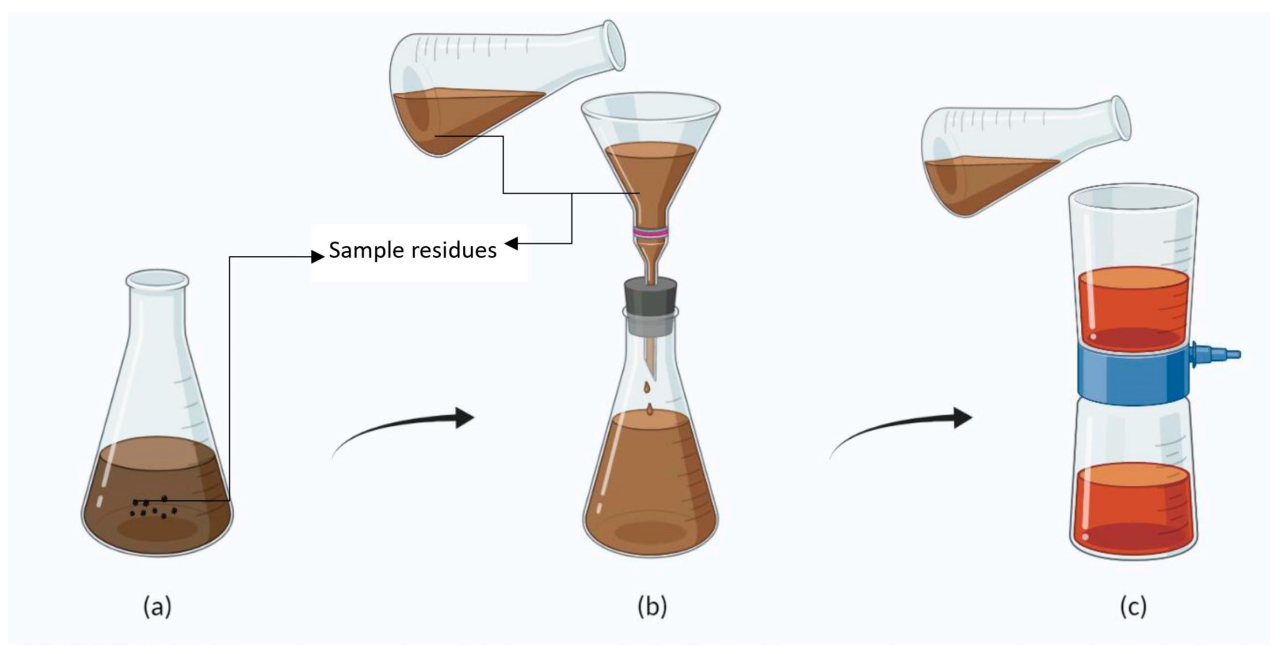

Filtering and clarifying honey after extraction

Filtering and clarifying are crucial steps to eliminate debris, wax particles, pollen grains, and other impurities that may have been introduced during extraction. These procedures enhance the honey’s visual appeal and prevent fermentation or spoilage caused by residual particulate matter.Filtering honey should be performed using clean, food-grade filters or sieves with fine mesh sizes, typically ranging from 100 to 300 microns, depending on the desired clarity.

It is recommended to pass the honey through multiple layers of filter media, starting with a coarser filter to remove larger debris, followed by finer filters for clarity.Clarification aims to reduce cloudiness and improve transparency. Common methods include:

- Settling: Allowing honey to rest in large, shallow containers for 24-48 hours to enable heavier particles to settle at the bottom, after which the clear honey can be gently decanted.

- Heat filtration: Slightly warming the honey to a temperature of around 40°C enhances fluidity, making filtration more effective without compromising quality. Care must be taken to avoid overheating, which can degrade honey’s enzymes and aroma.

- Use of fining agents: In commercial settings, authorized natural fining agents such as bentonite clay may be used to assist in removing suspended particles, followed by filtration.

It is essential to perform these steps in a hygienic environment to prevent contamination and ensure the honey remains pure and natural.

Cleaning and maintenance routines for the extractor

Maintaining the extractor in pristine condition is fundamental to ensuring the longevity of the equipment and the quality of the honey produced. Regular cleaning routines prevent bacterial growth, wax buildup, and cross-contamination between batches.Post-use cleaning should include:

- Disassembling the extractor components, such as drums, filters, and spindles, according to manufacturer instructions.

- Washing all parts with warm water and a mild, food-grade detergent to remove residual honey, wax, and debris.

- Using brushes or scrubbing tools to clean hard-to-reach areas, ensuring no residues are left behind.

- Rinsing thoroughly with clean water to eliminate soap residues that could interfere with honey quality.

- Drying all parts completely before reassembly to prevent mold and corrosion, especially in metal components.

- Applying a light coating of food-grade lubricant to moving parts if recommended, to ensure smooth operation during subsequent extractions.

Periodic maintenance should include inspection for wear and tear, tightening of bolts and fittings, and replacement of worn-out parts to uphold operational efficiency.

Organizing storage solutions for honey to preserve freshness and quality

Proper storage is vital for maintaining honey’s natural properties, preventing crystallization, fermentation, and contamination. Honey is best stored in conditions that inhibit microbial growth and preserve its aroma, flavor, and consistency.Optimal storage practices include:

- Using airtight, food-grade containers made of glass, stainless steel, or high-density polyethylene to prevent moisture ingress and contamination.

- Labeling containers with extraction date and batch details for traceability and quality control.

- Storing honey in a cool, dry place away from direct sunlight, ideally at temperatures between 10°C and 20°C. Excessive heat accelerates honey’s aging and can cause loss of quality.

- Avoiding temperature fluctuations that can lead to crystallization or fermentation.

- Ensuring containers are tightly sealed after each use to prevent moisture absorption, which can spoil honey or lead to fermentation.

For long-term storage, periodically checking honey for signs of fermentation, crystallization, or off-odor is advisable. If crystallization occurs, honey can be gently warmed to restore fluidity, provided it is done carefully to retain its nutritional qualities.

Safety and Troubleshooting Tips

Operating a honey extractor involves handling mechanical components and electrical systems, making safety a top priority. Proper precautions and maintenance are essential to prevent accidents, ensure the longevity of the equipment, and maintain the quality of honey extraction. Understanding common issues that may arise during operation allows beekeepers to troubleshoot effectively, minimizing downtime and preserving the integrity of the extraction process.

Implementing safety measures and conducting regular troubleshooting can significantly improve the efficiency and safety of honey extraction, protecting both the operator and the equipment. This section provides vital safety guidelines and troubleshooting strategies to optimize the use of honey extractors.

Safety Precautions During Operation of Mechanical Extractors

Ensuring safety during honey extraction involves a series of practices aimed at preventing injury and equipment damage. Since extractors often involve rotating parts and electrical components, adherence to safety protocols is critical. Proper training and awareness can reduce the risk of accidents and ensure smooth operation.

- Always wear protective gear, including gloves and safety glasses, to prevent contact with honey, sharp edges, or moving parts.

- Before starting the extractor, inspect all components for wear, damage, or loose fittings, and ensure the machine is properly grounded to prevent electrical shocks.

- Keep hands, clothing, and tools away from moving parts during operation to avoid entanglement or injury.

- Operate the extractor within the manufacturer’s specified speed limits to prevent mechanical strain or failure.

- Ensure the area around the extractor is clear of obstructions and that emergency stops are accessible and functional.

- Disconnect power before performing maintenance or clearing jams to avoid accidental activation.

Common Issues and Their Solutions

Despite careful operation, extractors may encounter issues such as motor failure or honey leakage. Recognizing these problems quickly allows for timely intervention, reducing downtime and potential damage.

| Issue | Description | Solution |

|---|---|---|

| Motor Failure | The extractor’s motor does not start or stops unexpectedly, often due to electrical or mechanical faults. | Check power supply and connections, reset circuit breakers if tripped, and inspect motor brushes or windings. Replace faulty motor parts or consult a professional if necessary. |

| Honey Leakage | Honey escapes from the drum or seals during operation, leading to wastage and contamination. | Ensure seals and gaskets are properly fitted and intact. Tighten or replace damaged seals, and avoid overfilling the drum. Regularly clean to prevent hardened honey from causing leaks. |

| Unusual Noise or Vibration | Excessive noise or shaking indicates misalignment or worn components. | Stop the extractor and inspect the drum, bearings, and drive belt. Lubricate moving parts if applicable, replace worn bearings, and realign components as needed. |

Maintenance and Troubleshooting Strategies for Longevity

Proper maintenance enhances the durability of honey extractors and ensures consistent performance. Regular checks and timely repairs prevent minor issues from escalating into costly damages.

- Perform routine inspections of electrical wiring, switches, and motor components, looking for signs of wear or corrosion.

- Lubricate moving parts according to manufacturer instructions to reduce friction and prevent overheating.

- Clean all parts thoroughly after each extraction session to prevent honey residues and microbial growth which can lead to corrosion.

- Replace worn or damaged seals, gaskets, and bearings promptly to avoid leaks and mechanical failure.

- Maintain a detailed log of maintenance activities and issues encountered to facilitate troubleshooting and identify recurring problems.

- Consult the extractor’s manual for specific maintenance schedules and recommended products to ensure compatibility and safety.

Regular maintenance and attentive operation significantly extend the lifespan of honey extractors, ensuring safe and efficient honey harvesting for years to come.

Tips for optimizing honey yield

Optimizing honey production involves strategic timing, efficient handling of honeycomb structures, and minimizing waste during extraction. By implementing best practices, beekeepers can ensure maximum harvests while maintaining hive health and sustainability. Proper techniques not only improve yield but also enhance the quality of honey, making the process more profitable and environmentally friendly.Effective honey harvesting requires careful consideration of various factors, including the natural cycle of honey flow, hive condition, and honeycomb characteristics.

Tailoring extraction methods to these factors can significantly boost yields and reduce unnecessary losses. The following strategies encompass timing, handling different honeycombs, and improving overall efficiency.

Timing honey harvests to maximize extraction

The timing of honey harvests plays a crucial role in ensuring high yields and maintaining hive vitality. Harvesting at the right moment allows for the collection of honey when it is fully ripened and has the optimal moisture content, preventing fermentation and spoilage.Beekeepers should monitor nectar flow and hive conditions closely. Typically, honey is ready for harvest when the bees cap the honey cells with wax, indicating that the moisture content has decreased to around 17-18%.

Harvesting too early results in honey with higher moisture, leading to fermentation, while delaying can cause nectar to crystallize or bees to re-seal honey cells, making extraction more difficult.It is also important to consider seasonal patterns. For example, in temperate regions, late spring or early summer often provides the peak nectar flow, making these periods ideal for harvesting. Conversely, avoiding harvests during rainy or cold spells helps prevent honey from absorbing excess moisture or becoming too viscous.

Handling different honeycomb types and honey viscosities

Honeycombs and honey viscosities can vary significantly based on the floral source, season, and hive conditions. Recognizing these differences allows for tailored extraction techniques that optimize yield and reduce damage to the combs.Frame types such as shallow or deep combs require specific handling approaches. Deep frames contain more honey but are often heavier and more prone to breakage if mishandled.

Shallow frames drain more easily but may hold less honey per frame. Beekeepers should select appropriate tools like heated knives or specialized uncapping tools that match the comb type to facilitate smooth removal.Honey viscosity depends on moisture content and floral origin. Thicker, more viscous honey (like nectar from certain forest blooms) may require gentle warming to flow freely. A controlled warm environment or a water bath setup can soften honey without compromising its quality.

Conversely, honey with lower viscosity flows easily but may be more prone to dripping during extraction, necessitating precise handling.Understanding these differences enables beekeepers to adjust their extraction techniques—such as using appropriate uncapping methods, heating, or pressure—to handle various honeycomb types efficiently.

Methods to improve efficiency and reduce waste in the extraction process

Maximizing honey yield involves streamlining procedures and minimizing waste during extraction. Proper organization and adherence to efficient practices can save time, reduce honey loss, and preserve comb integrity for future harvests.First, pre-warming honeycombs slightly before uncapping can make the process smoother and reduce honey leakage. Using sharp, well-maintained uncapping knives ensures clean cuts that minimize honey spillage and preserve comb structure.

Additionally, employing honey extractors with adjustable speed and gentle tumbling reduces the risk of comb breakage, allowing for repeated use and less waste.A systematic approach includes sorting combs based on honey content, wax buildup, or maturity, so that extraction resources are allocated efficiently. Utilizing gravity or centrifugal force effectively during extraction minimizes honey residue left in combs, leaving them in good condition for subsequent honey flows.Implementing a clean, organized workspace and using appropriate containers to collect honey prevents contamination and spillage.

Regularly inspecting equipment for wear and tear ensures smooth operation and reduces downtime.Finally, applying techniques such as dehumidifying honey during extraction—by slightly warming or using dehydration methods—can improve flow and reduce viscosity-related delays. Properly sealing and storing extracted honey in airtight containers prevents oxidation and spoilage, ensuring higher quality yields.

Efficient honey extraction balances timely harvesting, careful handling of combs and honey viscosities, and diligent process management—culminating in higher productivity and minimal waste.

Last Word

In summary, mastering how to extract honey with an extractor combines technical knowledge with careful handling to ensure the best possible yield and honey quality. Proper preparation, operation, and maintenance not only boost productivity but also extend the lifespan of your equipment. Implementing these best practices will help you enjoy a successful and rewarding honey harvesting experience.